Andys Handcuff Collection

"Making Of" Andy HS104 V2A

main page

1

[2]

[3]

[4]

[5]

[6]

[next]

How to make your own High Security Handcuffs

Selection of Cuff Style and Locks

There are some comfortable and some secure handcuffs. But most secure handcuffs are not very

comfortable (e.g. Hiatt HSS9, Peerless710, Rivolier with pin tumbler lock etc.). One of the

most comfortable handcuffs are Darbies, but they are not very secure. Many of them can be

rapped open or you can use a corkscrew, string or similar tool. Even you can use another not

exactly fitting Darby key, screw it about half turn in and pull on it.

What are really secure locks? I have successfully picked Hiatt HSS9, Rivolier and also Assa

Desmo from Peerless710 (of course "offhand"), locks should be more secure. I have some safe

locks from an old and empty bank building subject to demolition (bank has moved to a new

address, there were no news like "bank burglary: all locks vanished but no dollar missing"...).

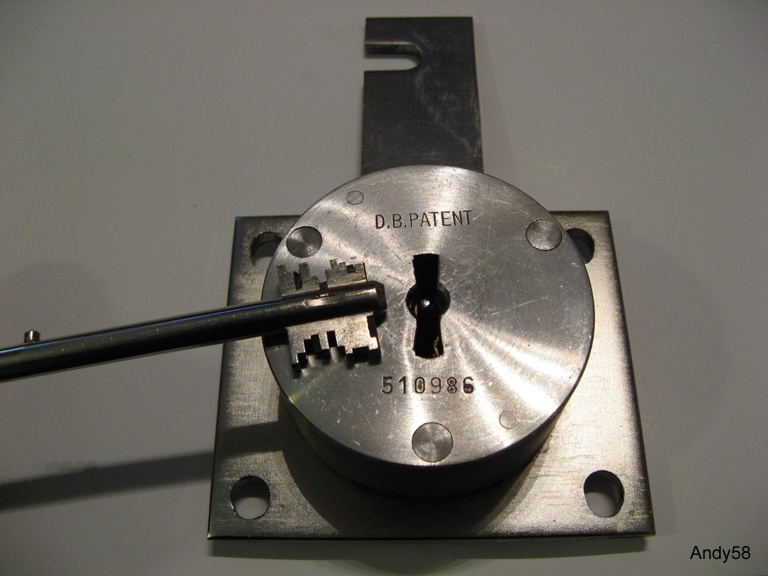

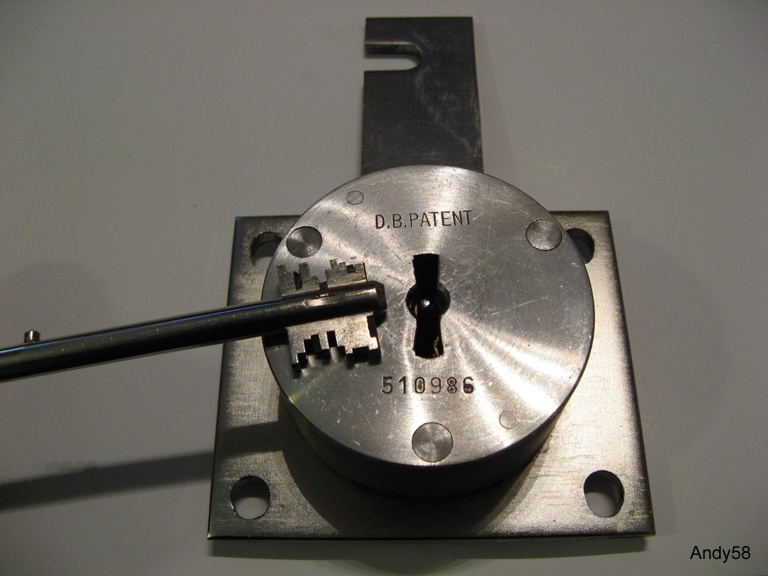

One of the most secure lock i have is a "Protector" from german lock factory Kromer, but

diameter is 78mm - too large for handcuffs - and too expensive (figure 1).

Figure 1: Kromer safe lock

For Handcuffs, locks must be smaller. Build in cylinders for cash boxes, lockers etc. have

much better dimensions. As i have seen cam locks from Abloy my idea was to build darby

handcuffs with them. I have ordered the latest model called "Protec" (figure 2).

Figure 2: Abloy cam lock Protec

My first prototype was made from ordinary steel (see

"Making Of" Andy HS104),

i planned to plate it with nickel. But plating was not successful. Plating in a bath of

electrolyte does not work - nothing happened, even after several hours. Tampon plating

with a sponge full of electrolyte worked, but plating was uneven and very thin. Unfortunately

it is a kind of nickel plating which becomes dirty if it has longer contact to sweaty skin.

The same nickel plating can be found on products from e.g. KUB, Victorworks or Clejuso #13.

You have to clean cuffs after every use. Better platings like Ian McColl, older Hiatt Darbies

etc. are not possible for me to do. So i removed plating from my prototype, but you have to

clean it regularly to prevent rust (but not after every use).

The new cuffs should be made of stainless steel because no plating is needed. I made a plan

what i am able to do with my tools from semi-finished parts (tubes, rods, flat bar steel etc.).

Among other hand operated tools there is a drilling machine, a small turning lathe, a small

milling machine and a welding apparatus for coated electrodes (without extra inert gas from

welding apparatus).

1

[2]

[3]

[4]

[5]

[6]

[next]